How Kinetic Lights Work: Motion Control, Light Engines, and Safety Systems

- Understanding the Engineering Principles Behind Kinetic Lights

- The Interaction Between Mechanical Movement and Digital Lighting

- Why Vertical Motion Creates a Stronger Spatial Illusion

- How Data, Power, and Motion Are Integrated Into One System

- Inside the Motion Control System

- How Lift Motors Convert Digital Signals Into Physical Movement

- The Role of Encoders in Position Tracking and Motion Precision

- How Winch Drums, Cables, and Pulleys Enable Vertical Travel

- Motion Algorithms That Control Acceleration and Deceleration

- Light Engines: How LEDs Deliver Color, Brightness, and Effects

- How LED Drivers Convert Commands Into Color Output

- Pixel Mapping Technology for Advanced Visual Patterns

- Optical Diffusion and Why It Matters for Kinetic Fixtures

- How Movement and Light Synchronization Is Achieved

- Timecode-Based Synchronization for Shows and Installations

- Data Routing Between Motion Controllers and LED Controllers

- How Designers Combine Light Effects and Motion Cues

- Safety Systems That Keep Kinetic Lights Stable and Reliable

- Load Detection and Anti-Drop Protection

- Dual-Brake Systems and Emergency Stop Protocols

- Structural Protection: Cables, Connectors, and Fire-Rated Materials

- Control Protocols That Run the Entire System

- How DMX and Art-Net Transmit Lighting Data

- Why Motion Systems Use CAN Bus or Proprietary Control Lines

- Integrating Both Systems Through a Unified Controller

- Real-World Workflow: From Programming to Live Operation

- Previsualization and Simulation Before Installation

- Addressing, Mapping, and System Calibration

- Running Live Shows, Monitoring Status, and Performing Maintenance

- What Affects the Performance of a Kinetic Lighting System?

- Motor Resolution, Cable Weight, and Winch Stability

- LED Quality, Heat Management, and Power Efficiency

- Environmental Conditions: Temperature, Height, Noise, Dust

- Conclusion

- FAQs

Understanding the Engineering Principles Behind Kinetic Lights

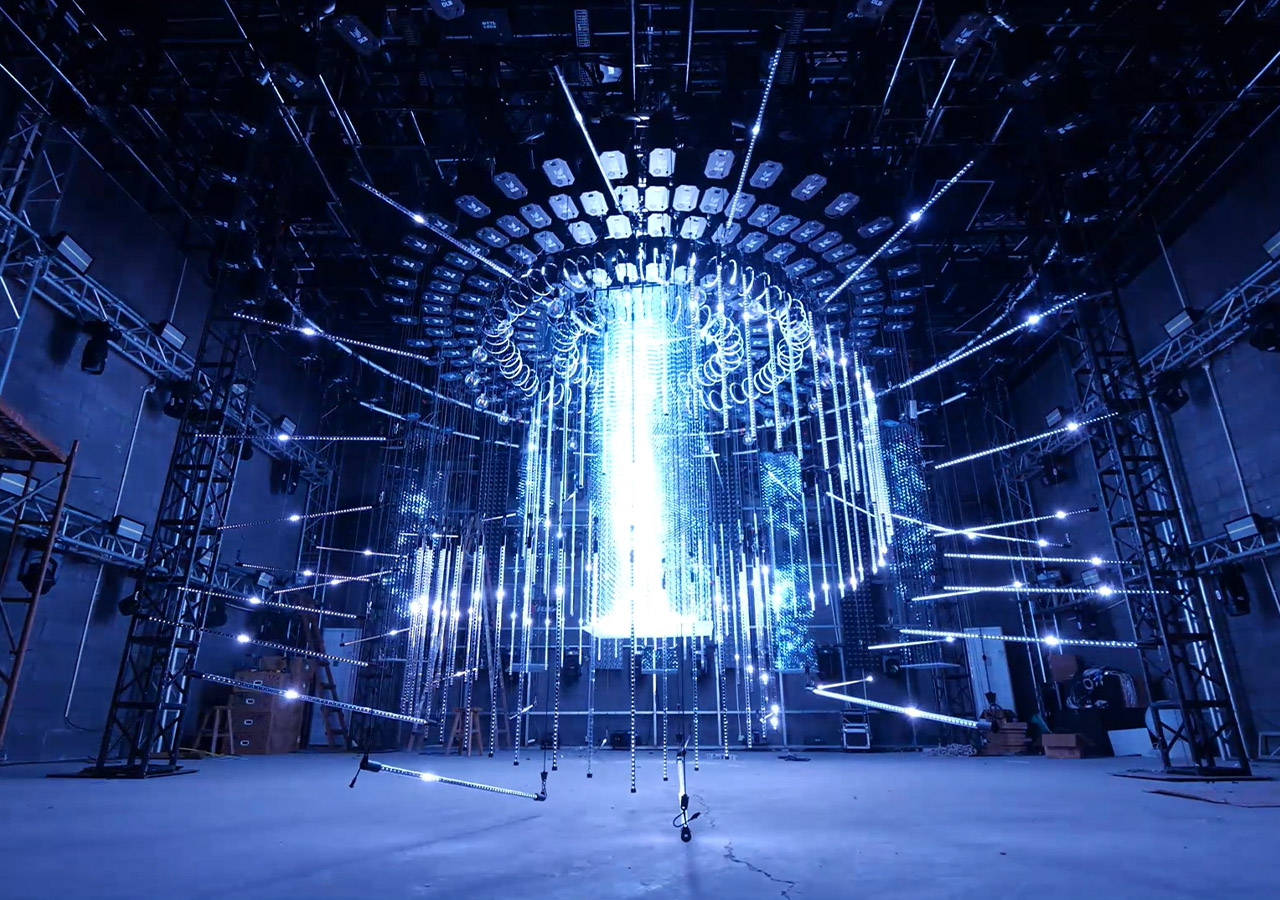

Kinetic lights are designed to be electromechanical and mechanical movements; LED lighting and real-time signal processing should be all in one coordinated system. In order to comprehend the kinetic lights in their entirety, it is important to consider them as active systems with motion physics, careful motor control and sophisticated digital lighting protocols and not just moving lights.

The Interaction Between Mechanical Movement and Digital Lighting

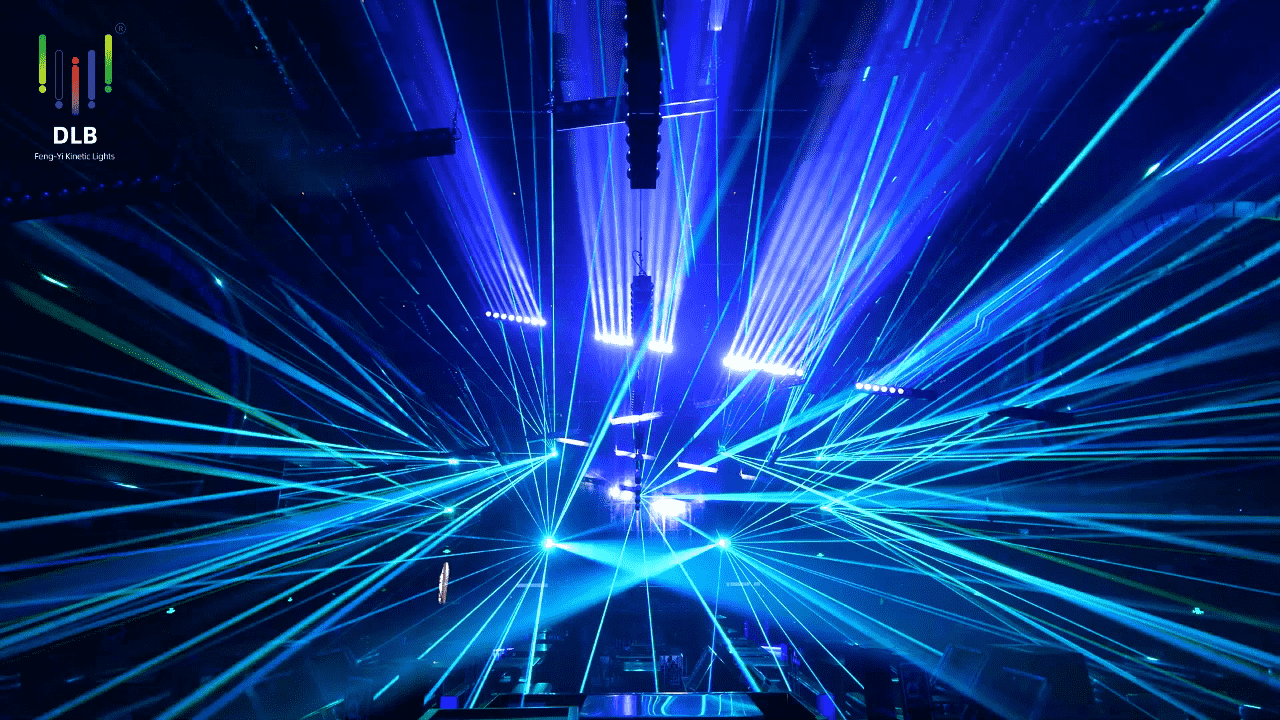

The kinetic light system is based on two large subsystems: the motion system (motors, encoders, winches) and the lighting system (LEDs, drivers, pixel processors). Whereas these subsystems are independent of one another, the data is shared between their controllers all the time. This real-time communication allows synchronized 3D motion combined with real-time color adjustment, dimming transitions, and pixel-mapped effects that transform as even motion paths.

Why Vertical Motion Creates a Stronger Spatial Illusion

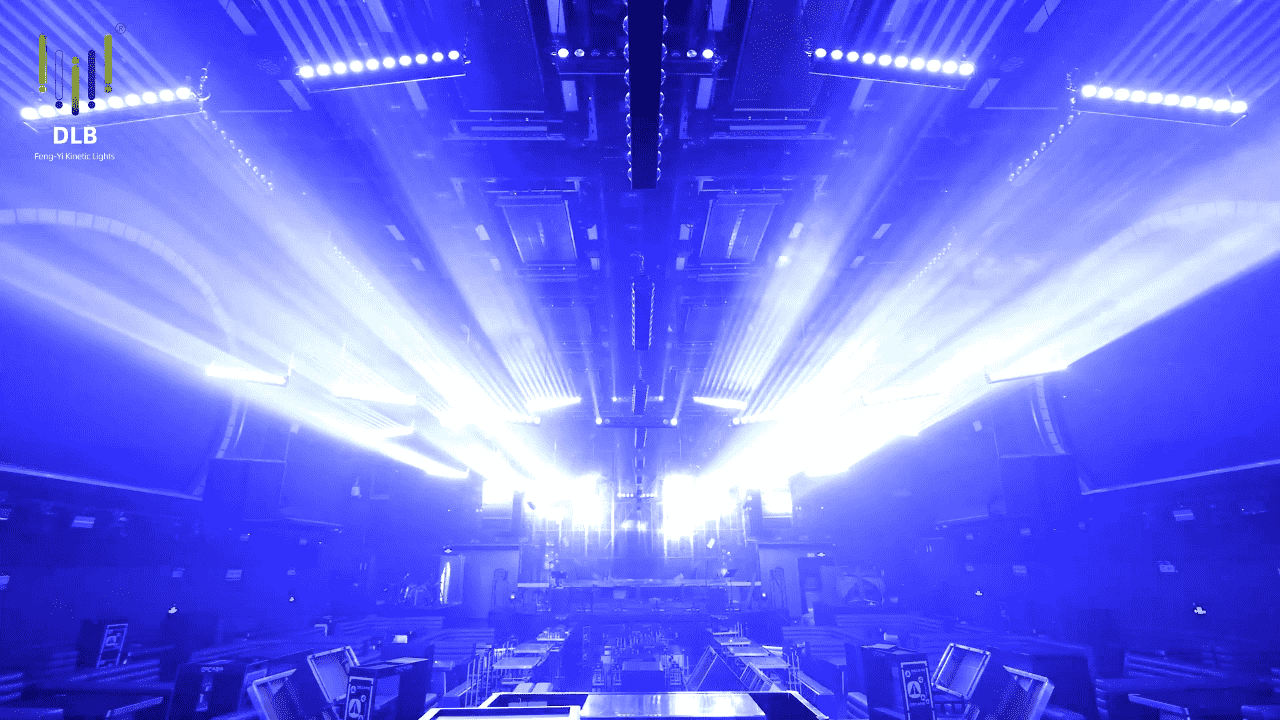

Vertical movement creates the most dramatic sense of space since height movement in the eyes of human beings is perceived as depth, scale and perspective. Sixty or hundreds of fixtures coming up and down together or in phase shifts produce building-like forms and immersive architectural sculptures, unattainable with other lighting types.

How Data, Power, and Motion Are Integrated Into One System

The complete assembly incorporates signal cables and power supply lines and mechanical elevating machines into small modules with high efficiency. Motion commands and LED control signals are supplied by data cables and high-density LEDs during motion are fed by power cables. The lifting cable does not only support the transmission of the fixture but also supports the constant feedback transmission and ensures the stability and accuracy during the full motion cycle.

Inside the Motion Control System

The mechanical foundation of the kinetic lights industry is the motion control system, which propels the vertical motion of lights accurately, consistently and safely.

How Lift Motors Convert Digital Signals Into Physical Movement

The controller sends digital movement cues to lift motors, which are typically servo motors or high-precision stepper motors. These indicators define the height of lift, velocity, acceleration and timing. These cues are changed into rotational energy by the motor, making the motor provide precise and repeatable up and down movement.

The Role of Encoders in Position Tracking and Motion Precision

The encoders serve as the position sensors of the system. They monitor the motor shaft rotation in real time and transform it into data of the distance and speed. This is to make sure that all the fixtures are moved to the actual programmed location without having drift, uneven movement, or position error during long show periods.

How Winch Drums, Cables, and Pulleys Enable Vertical Travel

This motor is connected to a winch drum with a special purpose, to either wind the lifting cable or unwind it. The cable path is stabilized by the pulleys and guiding structures to prevent the cable path from moving or oscillating laterally. The cable material, which is high-tension cable (mostly steel or aramid-core lines), is made to be durable with a constant mechanical load placed on it.

Motion Algorithms That Control Acceleration and Deceleration

Kinetic light control systems are based on motion algorithms, which form the acceleration and deceleration curves. These curves provide fluent starts and stops, mechanical component shock prevention and fluidity of the image. The sophisticated systems measure the torque, inertia and cable tension to ensure the same motion under the same load and environmental resistance of a given fixture regardless of the weight on the fixture.

Light Engines: How LEDs Deliver Color, Brightness, and Effects

The light engine is in charge of producing visual output out of motion. According to the kinetic lighting systems, LEDs should be stable, color-correct, and responsive even when they move vertically constantly. It needs high-level driver technology and an optimized design of the optical and data architecture that can support high-density pixel instructions with low latency.

How LED Drivers Convert Commands Into Color Output

LED drivers are considered the translator between light control protocols and the physical LED behavior. Once DMX or Art-Net data is loaded into the engine, it is processed by the driver to accept data on dimming values, color values and pixel effects. It then digitally controls voltage and current with very fine fine-tuning, usually 16 bits or more, to allow very smooth fades and mixes the colors with high accuracy.

High-frequency PWM (pulse-width modulation) is also used by professional-grade drivers and is used to avoid flicker even when the fixtures are being quickly moved or shot with high-speed cameras. This guarantees that all the kinetic lights are of equal output irrespective of their location or velocity of movement.

Pixel Mapping Technology for Advanced Visual Patterns

Pixel mapping enables the designers to address every kinetic fixture as addressable pixels in a bigger spatial canvas of 2D or 3D space. The system is capable of creating a dynamic effect, such as scrolling gradients, volumetric waves, or particle simulations or synchronized animation that changes with the motion of the fixtures by applying coordinates to every light.

The pixel mapping is particularly more potent when coupled with motion. An ascending motion may have a gradient assigned to it; a downward motion may be a so-called falling effect; a collection of items may become 3D objects that can be seen under various angles. It is this combination of movement and pixel contents that transforms kinetic lights to be spatial narration tools but not moving luminaires.

Optical Diffusion and Why It Matters for Kinetic Fixtures

Unless it is diffused adequately, the LED points will be ugly and jagged—particularly in cases where the lights are hung at different distances from the audience. The LED output is diffused using optical frosted acrylic, opal polycarbonate or micro-textured optical diffusers to produce a single surface of light.

This consistency is essential to the large installations where there are hundreds of fixtures forming a 3D volume. Diffusion also eradicates hotspots, minimizes glare and makes brightness aesthetically constant throughout motion. The outcome is a more unified visual field and a great betterment in spatial readability for the viewer.

How Movement and Light Synchronization Is Achieved

To be able to synchronize motion and lighting fully, a very coordinated workflow on control would be necessary. Both systems operate independently but they need to act as a seamless entity during a live performance. This synchronization makes all the rises and falls, color changes, and movements exactly timed.

Timecode-Based Synchronization for Shows and Installations

Lighting, motion, video, and audio systems are synchronized using timecode formats, e.g. SMPTE or MIDI. Timecode ensures that a single master timeline is used throughout the show since each cue is assigned a specific time.

This accuracy is critical to installations with dozens or hundreds of kinetic fixtures. Even the delay of 100 milliseconds might lead to visual confusion or disconnect the illusion of coherent movement. Timecode eliminates such problems and enables the designers to design choreography with a precision of milliseconds.

Data Routing Between Motion Controllers and LED Controllers

Lighting and motion controllers (DMX / Art-Net, CAN Bus / proprietary) are managed on different data networks, as they require different bandwidth and latency requirements. Those networks are united in a master controller, which manages both streams of data as well as makes sure they will be carried out in the right order.

In this architecture, bottlenecks in communication are eliminated and motion cues, speed curves, and lighting effects are generated at precisely the right time even when the system is severely loaded with data or executing complicated pixel animations.

How Designers Combine Light Effects and Motion Cues

Light effects on motion paths are another way of creating visual complexity by the designers. One of the fixtures may travel vertically as it changes from warm white to icy blue or a falling array may travel with a pixel rain effect moving down. These two cues combine in order to create the emotional mood and spatial story of the installation.

Designers can achieve the feeling of alive, rhythmic, and sculptural by treating motion as structure and lighting as an expression.

Safety Systems That Keep Kinetic Lights Stable and Reliable

Kinetic lights are used above performers, audiences and treasured stage equipments. Safety is not a feature as such, but an underlying engineering concern. Each element of the motor to the cable should be made to operate under mechanical stress in the long run.

Load Detection and Anti-Drop Protection

The high-end load sensors are used to monitor cable tension and weight of the fixtures. In case the system notes any abnormality, like high resistance, sudden slack or unpredictable force, the system stops and switches on protective measures.

Even under extreme conditions, fixtures can not fall freely but rather they have anti-drop mechanisms, whether it is mechanical locks or fail-safe catch mechanisms.

Dual-Brake Systems and Emergency Stop Protocols

Professional lifting systems use redundant brakes:

- Mechanical brakes lock the winch physically

- Electronic brakes apply holding torque through the motor system

They are used together to give multiple protection against power outages or mechanical failures. Emergency stop buttons, which are also fitted in the control panels and remote units, enable operators to immediately stop the whole system under the event that there are abnormalities.

Structural Protection: Cables, Connectors, and Fire-Rated Materials

All structural components must withstand constant motion, vibration, and heat:

- High-tensile steel cables ensure strength and durability

- Industrial-grade connectors prevent data or power interruptions

- Fire-rated materials reduce ignition risks in hot environments

These protections maintain reliability during long-term installations or touring productions.

Control Protocols That Run the Entire System

Communication protocols determine the rate of responsiveness of the kinetic lighting system in responding to operator instructions and the accuracy with which it responds. The selection of the proper protocol will guarantee a consistent behavior of the performance in terms of lighting, motion, and pixel mapping.

How DMX and Art-Net Transmit Lighting Data

DMX512 is the standard lighting control in the industry that is stable and has low latency. Art-Net or sACN is used in systems with many pixels or high-density arrays to spread the lighting information effectively to Ethernet networks and achieve kinetic displays of large scale.

Why Motion Systems Use CAN Bus or Proprietary Control Lines

Motion systems require extremely precise communication with minimal latency. CAN Bus stands out because it offers:

- High-speed data transfer

- Strong resistance to electromagnetic interference

- Multi-node communication reliability

This ensures that motor commands and encoder feedback operate without interference or delay.

Integrating Both Systems Through a Unified Controller

A single controller combines all the lighting and movement effects into a single programming interface. This makes the workflow easier, minimizes synchronization errors and enables the designers to work with lighting and motion behavior simultaneously as opposed to having to work in different systems.

Real-World Workflow: From Programming to Live Operation

Implementation of a kinetic lighting system would involve all technical processes, which would involve planning, simulation, calibration and monitoring of the systems over a long period of time.

Previsualization and Simulation Before Installation

Before hardware installation, designers use simulation software to preview:

- Fixture locations

- Motion paths

- Lighting effects

- Collision risks

This stage allows teams to optimize choreography and ensure safety without using physical equipment.

Addressing, Mapping, and System Calibration

Each fixture is assigned:

- A lighting address (DMX/Art-Net)

- A motion address (CAN Bus)

Calibration then sets:

- Motor travel limits

- Torque and speed settings

- LED color accuracy

- Pixel mapping positions

These parameters ensure consistent and predictable performance.

Running Live Shows, Monitoring Status, and Performing Maintenance

In operation, technicians are able to observe real-time diagnostics of the system like motor temperature, encoder readings, load tension, lighting data integrity and error logs. Periodic maintenance lubrication, cable tests and driver tests make the touring and permanent installations stable in the long run.

What Affects the Performance of a Kinetic Lighting System?

The performance of a kinetic lighting system depends on a number of engineering factors that give it a smooth and reliable performance.

Motor Resolution, Cable Weight, and Winch Stability

- Motor resolution defines how fine the movement increments can be

- Cable material and weight impact lifting speed and stability

- Winch design affects vibration, movement accuracy, and long-term reliability

These factors directly determine the visual smoothness of kinetic motion.

LED Quality, Heat Management, and Power Efficiency

LED performance depends on:

- High-quality diodes for consistent color

- Effective heat dissipation for long lifespan

- Efficient drivers to prevent flicker or color shifting

Poor thermal control can degrade LEDs rapidly, reducing performance over time.

Environmental Conditions: Temperature, Height, Noise, Dust

Installations in hot, dusty, or open-air environments require enhanced protection, such as

- Sealed housings

- Reinforced cable routing

- Additional cooling solutions

Proper environmental engineering ensures longevity and safety.

Conclusion

Kinetic lighting systems are based on the integration of high-level precision mechanics with the latest LED engines with smart safety systems to provide dynamic, volumetric, and immersive lighting experiences. Through the insights into the operation of kinetic lights, including motion algorithms, LED control and real-time data responses, designers and integrators can harness the entire creativity of dynamic lighting.

When you need a dependable collaborator in the production of high-precision kinetic lighting, FENG-YI will provide you with professional engineering, long-lasting lift systems, customizable lighting, and strong project services to the entertainment, architectural, and experience design sectors.

FAQs

1. What makes kinetic lights different from standard LED lights?

Kinetic lights are able to move through motorized winches and coordinate lighting effects to form 3D visual structures.

2. How are kinetic lights controlled?

DMX/Art-Net is used in lighting effects and CAN Bus or proprietary controllers are used in motion.

3. Are kinetic lights safe for installation above audiences?

Yes, fitted with load sensors, dual brakes, certified cables and safety monitoring systems.

4. Can kinetic lights run continuously in long-term installations?

Quality kinetic lights that are well cooled, have long-lasting motors and good control systems can last throughout the year.

5. Can kinetic lights be customized?

Surely FENG-YI offers tailor-made pixel density, size of the fixtures, diffusion, motion range and system integration.

Wedding & Parties Lighting Solutions

Are there minimum requirements for venue ceiling height and load capacity?

We recommend a clear height of ≥6–8 m (higher may be required for choreography needs). Load capacity is calculated based on point load plus safety factor. We provide structural calculations and suspension point recommendations.

Nightclub Lighting

Can the lighting, screens, and other equipment be combined to achieve integrated sound, lighting, and visuals?

Programming is possible through Madrix and MA consoles, using timecode synchronization to achieve a precise "programmed show" effect.

Will the equipment break down easily? How long is the after-sales service?

Our products are designed specifically for the entertainment industry. They feature excellent heat dissipation and can withstand the harsh, high-temperature, high-humidity, and dusty environments of bars. They are guaranteed to operate continuously for 2,000 hours. We offer a one-year warranty starting from the date of delivery (excluding consumables such as bulbs and LEDs). If the product is damaged due to quality issues, the seller will provide a replacement free of charge.

Products

What is the service life of LED lamp beads? Is professional personnel required for later replacement?

All our lights adopt imported LED chips, with a service life of ≥ 50,000 hours under normal use (8 hours of daily use can last for 17 years). The replacement of lamp beads requires professional operation—due to the involvement of wire soldering and heat dissipation adaptation, unprofessional operation may cause short circuits or uneven light effects. You can contact the after-sales team for on-site replacement or repair-by-mail services.

Want to learn more about the latest updates?

Have questions or ready to illuminate your project? Reach out to our expert team today.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

By clicking "Send your message," I agree to your processing my personal data.

To see how to withdraw your consent, how to control your personal data, and how we process it, please see our Privacy Policy and Terms of Use.

© 2025 FENG-YI. All Rights Reserved.

Facebook

Instagram

YouTube

TikTok