Understanding the Key Aspects of Stage Mechanical Maintenance and Servicing

Explore the core dimensions of stage mechanical maintenance and servicing to ensure the safe, stable, and efficient operation of theater equipment, meeting the demands of various performances.

Explore the core dimensions of stage mechanical maintenance and servicing to ensure the safe, stable, and efficient operation of theater equipment, meeting the demands of various performances.

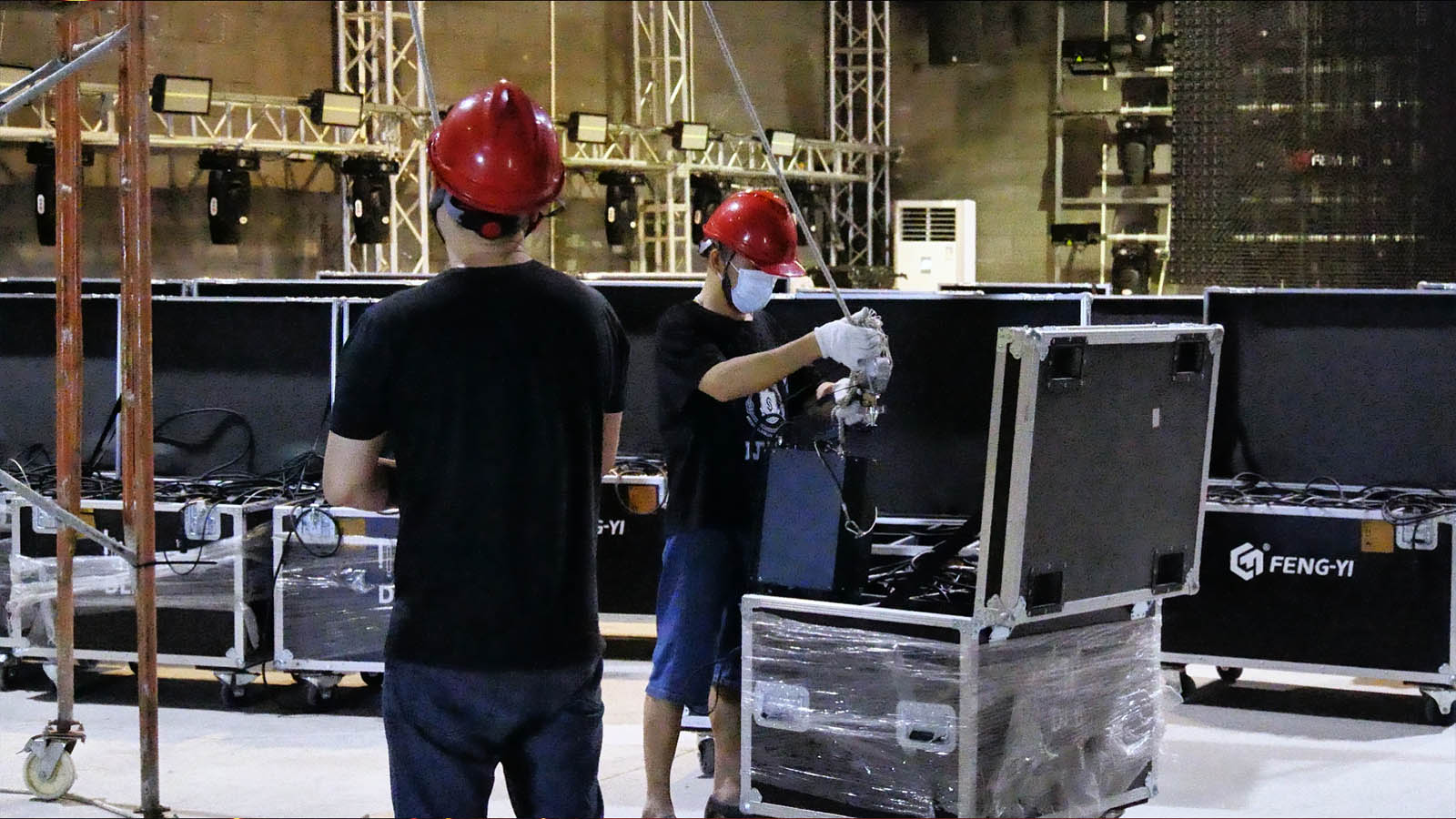

In the realm of theater operations and performance guarantees, stage mechanical equipment serves as the backbone of smooth performances. From lighting systems that shape the atmosphere to mechanical systems that drive scene changes, their reliable operation directly impacts the quality of performances and operational safety. Due to high-frequency use and complex working environments, stage machinery is prone to wear, aging, and malfunctions. Inadequate maintenance not only leads to equipment damage but also poses significant safety risks. Therefore, systematic and standardized maintenance and servicing of stage machinery are of paramount importance. Let’s delve into the key aspects that constitute effective stage mechanical maintenance.

1. Stage Lighting Circuit Overhaul

The lighting circuit is the "nerve network" of stage lighting systems, and its stability directly determines the normal operation of lighting equipment and performance safety. This overhaul focuses on eliminating potential electrical hazards and ensuring reliable circuit operation.

Full Circuit Replacement: Replace the entire stage lighting circuit to eliminate hidden dangers such as aging, oxidation, or insulation damage of old circuits, ensuring the circuit system is stable, intact, and meets safety standards.

Fireproof Component Accessory Replacement: Replace accessories for key fireproof components (e.g., junction boxes, connection boxes). These components play a critical role in preventing electrical fires; replacing worn or aging accessories ensures their fireproof performance and structural stability.

Connector Standardization: Rectify and standardize connectors that do not meet safety requirements. Loose, mismatched, or substandard connectors are prone to poor contact, arcing, or overheating. Standardized installation ensures stable current transmission and safe operation of the entire circuit.

2. Stage Mechanical System Maintenance

Stage mechanical systems (e.g., booms, hoists, and lifting platforms) bear the load of scene changes, prop lifting, and actor movement, making their structural and control stability essential for performance safety.

Mechanical Component Inspection and Repair: Conduct a comprehensive inspection of core moving components such as steel wire ropes, pulleys, brakes, and clutches. Check for wear, deformation, or fatigue of steel wire ropes—replace severely worn ones and repair slightly damaged ones. Ensure pulleys rotate flexibly without jamming, and verify that brakes and clutches engage/disengage accurately to guarantee the stable, safe operation of boom and hoisting mechanical systems.

Electrical Control Cabinet Overhaul: Perform a full inspection of the control cabinet for the boom electrical control system and other mechanical electric control systems. Check wiring terminals for looseness, inspect circuit boards and components for burnout or failure, and replace faulty parts in a timely manner. This ensures the control cabinet can accurately receive and execute operation commands, maintaining the stable and safe operation of the mechanical electrical control system.

3. Stage Lighting Adjustment and Maintenance

Beyond hardware maintenance, lighting adjustment and program optimization directly affect the expressive effect of stage lighting, ensuring it aligns with creative requirements for performances.

Position and Brightness Adjustment: Based on the actual needs of different performances (e.g., drama, dance, concert), adjust the angle, height, and brightness of lighting fixtures at various positions. Fine-tune until the lighting meets the artistic conception of the performance and satisfies the user’s (director, lighting designer) requirements.

Lighting Control Program Reprogramming: Recompile and optimize lighting control programs according to updated performance lighting plans. Ensure the program can accurately trigger lighting changes, color transitions, and effect switches in sync with the performance rhythm, achieving seamless integration of lighting and performance content.

4. Stage Lighting System Inspection and Maintenance

This aspect focuses on the integrity and functionality of lighting fixtures themselves, ensuring the basic lighting needs of the stage are met without interruptions.

Full Fixture Inspection and Bulb Replacement: Conduct a one-by-one inspection of all stage lighting fixtures (e.g., spotlights, floodlights, moving head lights). Check for flickering, dimming, or non-illumination issues. Replace aging, burned-out, or low-luminance bulbs promptly to ensure each fixture operates stably, providing sufficient and consistent brightness for the stage.

FAQs:

How often should stage mechanical systems undergo comprehensive maintenance?

The frequency depends on usage intensity. For theaters with daily performances, comprehensive maintenance is recommended every 3–6 months; for those with occasional use, it can be conducted annually. Additionally, a quick inspection should be performed before each major performance.

Is it necessary to hire professionals for a stage lighting circuit overhaul?

Yes. Stage lighting circuits involve high voltage and complex wiring. Professional technicians with electrical qualification certificates can identify hidden dangers accurately and operate in compliance with safety standards, avoiding electrical accidents caused by improper operation.

Conclusion:

Stage mechanical maintenance and servicing is a systematic project covering circuits, machinery, lighting adjustment, and fixture maintenance. Each aspect is interconnected and equally important—circuit overhaul lays the foundation for safety, mechanical system maintenance ensures operational stability, lighting adjustment enhances artistic expression, and fixture inspection guarantees basic functionality. By implementing standardized maintenance in these key areas, theaters can not only extend the service life of equipment but also eliminate safety risks, ensuring performances proceed smoothly and perfectly present artistic works to the audience. Regular maintenance is not just a "protective measure" for equipment but also a "commitment" to performance quality and audience safety.

Wedding & Parties Lighting Solutions

Is the control system compatible with existing consoles?

Supports DMX / Art-Net / sACN for seamless integration with mainstream consoles; also enables Timecode-driven operation and multimedia synchronized control.

How is safety ensured?

Encoder closed-loop control, emergency stop circuits, software/hardware limit switches, load monitoring, and collision-avoidance zones. A comprehensive pre-performance checklist is provided.

Is system operation quiet?

We offer noise-optimized solutions (vibration damping/soft start/low-noise wire rope guidance) to meet acoustic requirements for TV studios and commercial spaces.

Customization/OEM Services

What customization services can you provide? For example, adjustments to appearance, functions, or parameters.

Multi-dimensional customization is supported:

▪ Appearance customization: Lamp housing colors (e.g., in addition to black and silver, exclusive brand colors can be customized), and laser engraving of the brand logo on the body.

▪ Function customization: Adjustment of channel modes (e.g., adding exclusive light control channels), adaptation of light control protocols (e.g., compatibility with the customer's own central control system), and special scenario functions (e.g., increasing the waterproof level of outdoor models to IP65).

▪ Parameter customization: Extended stroke of elevating lights (default 0-5 meters, customizable up to 10 meters), adjustment of the beam angle of conventional lights (e.g., custom 15° narrow beam angle for PAR lights).

Want to learn more about the latest updates?

Have questions or ready to illuminate your project? Reach out to our expert team today.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

By clicking "Send your message," I agree to your processing my personal data.

To see how to withdraw your consent, how to control your personal data, and how we process it, please see our Privacy Policy and Terms of Use.

© 2025 FENG-YI. All Rights Reserved.

Facebook

Instagram

YouTube

TikTok